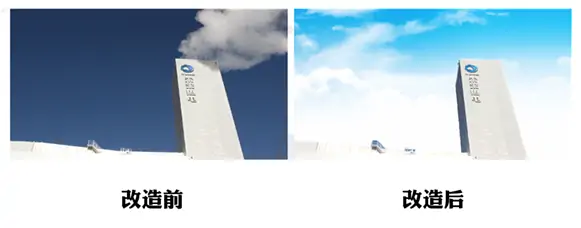

Beijing Jingneng Future Gas Power Plant Flue Gas Deoxidation and Waste Heat Utilization Project

Project Introduction

Beijing Jingneng Future Gas-fired Thermal Power Co., Ltd. uses gas-steam combined cycle to generate electricity and is also responsible for heating in the surrounding areas. It has implemented deep recovery of waste heat from its gas turbine exhaust, recovering a total of 48MW of waste heat and providing a total heating capacity of 112MW. This is also the first time in the world that deep recovery technology for flue gas waste heat has been applied to a gas-fired power plant.

Development Background

Natural gas boiler heating and gas power plant power generation are limited by the high return water temperature of the heating network. The boiler exhaust temperature is difficult to reduce, resulting in low energy utilization of natural gas, high heating costs and white smoke, which affects the urban landscape. The water vapor in the exhaust contains a large amount of latent heat of vaporization. If it can be recovered and utilized, it can greatly improve the energy utilization efficiency of natural gas and reduce heating costs.

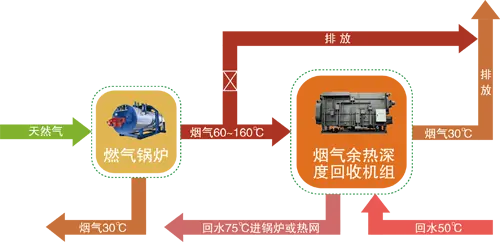

Process Diagram

Technical advantages

1. The exhaust gas temperature of gas boilers is reduced to below 30℃;

2. The utilization rate of natural gas is increased by more than 10%;

3. The emission of pollutants such as NOx and SO2 in flue gas is reduced, and the white smoke phenomenon is eliminated;

4. The unit can be used for cooling in summer, and one machine can be used for two purposes.

Application Description

After natural gas is burned in a gas boiler, the flue gas generated enters the flue gas waste heat deep recovery unit. The deep recovery of heat in the flue gas greatly reduces the exhaust temperature. The recovered heat is used to heat the return water of the heating network or directly provide heating.