Jinan Beijiao Power Plant Coal-fired Boiler Flue Gas Whitening Deep Pollution Reduction Waste Heat Recovery Project

Project Introduction

Jinan Beijiao Thermal Power Plant is affiliated to Jinan Thermal Power Co., Ltd., which mainly provides urban heating and also provides electricity, steam, hot water, etc. In 2015, the Beijiao Thermal Power Plant implemented deep pollution reduction and waste heat recovery of flue gas on the coal-fired boiler, which greatly reduced the exhaust temperature and used the recovered waste heat for heating. At the same time, it reduced the emission of dust, sulfide and nitrogen oxide in the flue gas, achieving multiple effects of energy saving, environmental protection and water saving. This is the first time in the world that the deep recovery technology of flue gas waste heat has been successfully applied to a coal-fired power plant.

Development background

On December 2, 2015, the State Council decided to “fully implement ultra-low emission and energy-saving transformation of coal-fired power plants”. The flue gas discharged from coal-fired boilers has an exhaust temperature of about 52°C after desulfurization. The flue gas carries a large amount of water vapor, but the composition is complex, corrosive, and there are many recycling technology bottlenecks. If these world-class problems can be successfully solved and recycled, multiple effects such as energy saving, environmental protection, and water saving can be achieved.

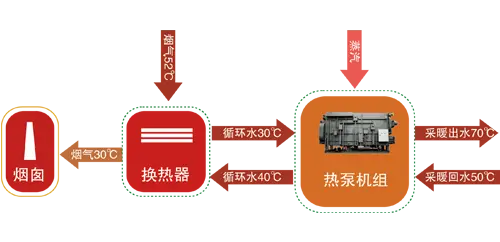

Process diagram

Application Description

The flue gas generated by the combustion of coal-fired boilers enters the heat exchanger after wet desulfurization, deeply recovers the latent heat and sensible heat in the flue gas and reduces the emission of pollutants, which greatly reduces the exhaust temperature of the boiler. The recovered heat is used to heat the return water of the heat network or direct supply.

Technical advantages

1. The exhaust temperature of coal-fired boilers is reduced to below 30℃;

2. The efficiency of coal-fired boilers is increased by more than 10%;

3. Reduce the emission of pollutants such as dust, NOx, SO2 in the flue gas, and eliminate the phenomenon of white smoke;

4. The unit can be used for cooling in summer, and one machine can be used for two purposes.