Core Advantages

Highly Efficient Moisture Removal:

- The zeolite rotor efficiently adsorbs moisture from the air, utilizing the unique properties of zeolite materials. This process allows for superior dehumidification performance, especially in low humidity conditions, making it ideal for applications that require precise humidity control.

Energy Savings and Sustainability:

- By integrating the zeolite rotor with advanced thermal regeneration methods, the machine minimizes energy consumption compared to traditional dehumidification systems. This not only reduces operational costs but also supports sustainable practices by decreasing the overall carbon footprint of the dehumidification process.

High Dehumidification Efficiency

Energy Efficiency:

Environmentally Friendly:

Wide Operating Temperature Range:

Long Service Life and Durability:

Compact Design:

High Dehumidification Efficiency:

- The zeolite rotor effectively adsorbs moisture from the air, providing superior dehumidification performance, especially in low-humidity environments. This efficiency allows for precise control of humidity levels, making it ideal for various industrial and commercial applications.

Energy Efficiency:

- The design of the zeolite rotor enables low energy consumption during operation, reducing overall operational costs. The thermal regeneration process allows for effective moisture removal without requiring excessive energy input, making it more economical than traditional dehumidification methods.

Environmentally Friendly:

- Zeolite materials are natural and sustainable, contributing to environmentally friendly practices. The system minimizes the use of harmful refrigerants and reduces energy consumption, resulting in a lower carbon footprint.

Wide Operating Temperature Range:

- The zeolite rotor integrated machine operates effectively across a broad range of temperatures, making it versatile for various applications, from industrial processes to residential settings.

Long Service Life and Durability:

- Zeolite rotors are designed to withstand repeated cycles of moisture adsorption and desorption, resulting in a long service life. Their robust construction ensures reliability and durability over time, reducing the need for frequent replacements.

Compact Design:

- The integrated nature of the zeolite rotor system allows for a more compact design compared to traditional dehumidifiers. This space-saving feature makes it easier to install in various settings, from industrial facilities to smaller commercial spaces, without compromising performance.

Product Specifications

| Product Specification | Details | Product Specification | Details |

| Heating Power | 6.0 kW | Energy Efficiency Rating | A++ |

| Refrigerant Type | R410A | Applicable Area | 50-150㎡ |

| Power Supply Voltage | 220V / 50Hz | Noise Level | ≤25 dB |

| Dual Inverter Technology | Supported | Smart Temperature Control | Supported |

| Remote Control | Mobile App Remote Control | Auto Defrost Function | Supported |

| Operating Temp Range | -15℃ to 45℃ | Weight | 40 kg |

| Dimensions (L x W x H) | 850mm x 300mm x 650mm | Installation Method | Ceiling / Wall Mounted |

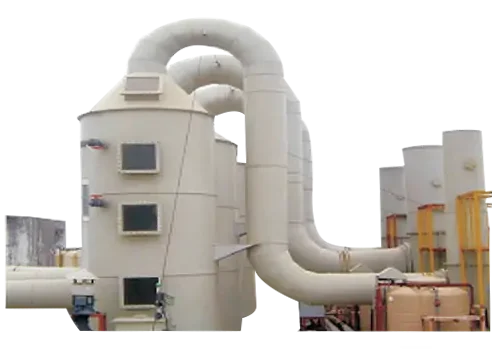

Waste heat source heat pump unit Feature and Application:

Zeolite Adsorption Rotor:

The system features a specialized zeolite rotor that adsorbs moisture efficiently from the air. Zeolite’s high moisture affinity allows for precise and effective dehumidification, even in low-humidity environments.

Thermal Regeneration System

The machine includes a thermal regeneration process that heats the rotor to release the adsorbed moisture, ensuring continuous operation without frequent maintenance. This feature enhances efficiency while minimizing energy consumption.

Integrated Air Handling System:

The machine combines air filtration, moisture control, and temperature management into a single system, providing a comprehensive air treatment solution. This integration allows for improved indoor air quality and precise climate control.

Compact and Modular Design:

The system is designed to be compact and modular, making it easy to install in various spaces. The integrated components reduce the need for external systems, saving both space and installation costs while maintaining high performance.

Application:

Industrial Processes:

Used for precise humidity control in manufacturing processes, such as tablet production and storage, where maintaining low moisture levels is critical for product stability.

Food Processing and Storage:

Ensures controlled humidity levels to prevent spoilage, mold growth, and moisture-related issues in food drying, packaging, and storage facilities

Electronics Manufacturing:

Provides a low-humidity environment to prevent moisture damage and corrosion during the production and storage of sensitive electronic components.

Clean Rooms:

Essential for maintaining controlled environments in industries like biotechnology, aerospace, and semiconductor manufacturing, where humidity control is crucial for product quality and process integrity.

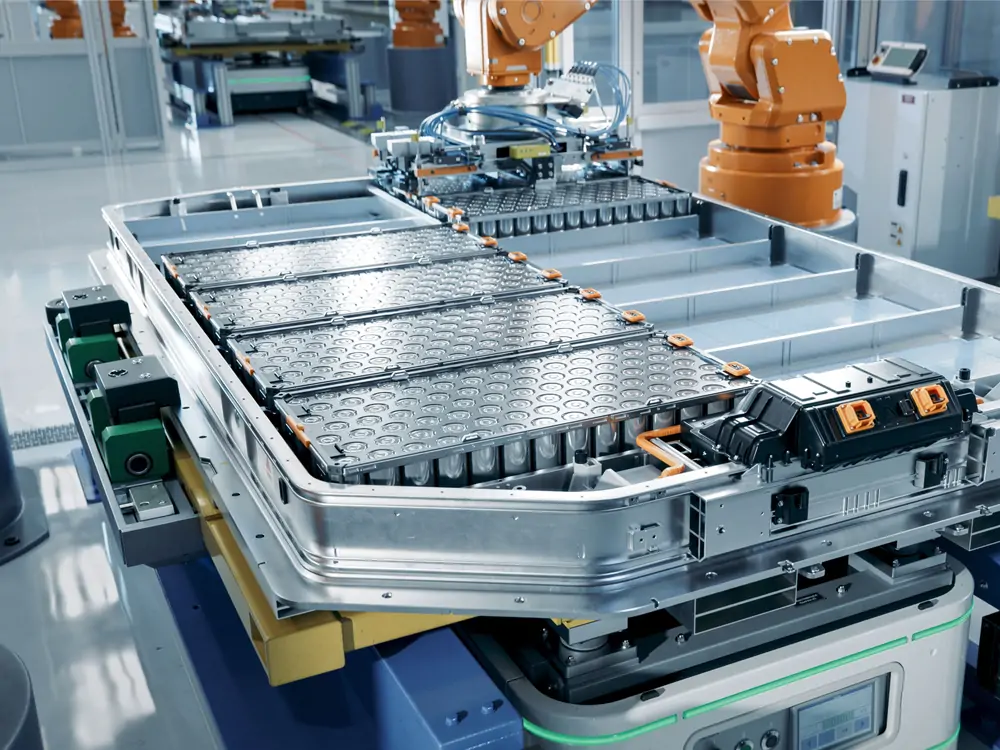

Lithium Battery Production:

Ensures dry air conditions in the production of lithium-ion batteries, where exposure to moisture can degrade battery performance and reduce product lifespan.

Museums and Archives:

Maintains optimal humidity levels to preserve delicate artifacts, documents, and artwork, preventing damage from excess moisture or humidity fluctuations.

Complete zeolite rotor integrated machine Details

Working Principle:

complete zeolite rotor integrated machine is based on the adsorption and desorption of moisture using a rotating zeolite rotor. The process begins as air is drawn into the system, passing through a filtration system to remove particles. The filtered air then moves through the zeolite rotor, where the zeolite material adsorbs moisture from the air, significantly reducing its humidity. The basic steps include:

Air Intake and Filtration:

Air is drawn in and filtered to remove particles.

Moisture Adsorption:

The air passes through the rotating zeolite rotor, which adsorbs moisture.

Thermal Regeneration:

The rotor moves into the regeneration zone, where heated air removes the adsorbed moisture

Dry Air Distribution:

The dry, treated air is supplied to the intended area, completing the dehumidification process.

Efficiency and Performance:

complete zeolite rotor integrated machine are driven by its ability to provide continuous, energy-efficient dehumidification. The system uses zeolite material for effective moisture adsorption, even in low-humidity conditions, ensuring high-performance air drying. Its thermal regeneration process allows the rotor to be continuously refreshed with minimal energy use, leading to lower operational costs compared to traditional dehumidification methods. Additionally, heat recovery systems integrated within the unit further enhance energy efficiency by reusing heat from the regeneration process. This results in consistent performance, long service life, and reduced environmental impact, making it ideal for industrial and commercial applications.

Frequently asked questions

The machine uses a rotating zeolite rotor that adsorbs moisture from incoming air. As the rotor rotates, a thermal regeneration process heats part of the rotor to release the adsorbed moisture, allowing continuous dehumidification.

Key benefits include high efficiency, low energy consumption due to thermal regeneration, and effective moisture control, even in low-humidity conditions. It also reduces energy costs and has a long service life.

Zeolite rotor systems are ideal for industrial, commercial, and specialized applications like pharmaceutical production, food storage, electronics manufacturing, and clean rooms, where precise humidity control is essential.

Regular maintenance includes cleaning or replacing air filters, checking the rotor for any wear, and ensuring the regeneration system is functioning correctly. The system generally requires minimal upkeep.

The system is highly energy-efficient due to the zeolite’s moisture adsorption capability and the thermal regeneration process, which recycles heat for continuous operation. Heat recovery options can further enhance energy savings.

With proper maintenance, a zeolite rotor can last 10 to 15 years or more, depending on operating conditions and the intensity of use. Its durability makes it a cost-effective solution over the long term