Core Advantages

Energy-Efficiency and Performance

- Water-cooled centrifugal units are highly energy-efficient, with a high-speed rotating compressor enabling large refrigerant flow and efficient heat exchange. The water-cooling system provides better heat dissipation and a higher coefficient of performance (COP). They also offer a wide range of cooling capacities, suitable for large-scale commercial and industrial facilities.

Reliability and System Compatibility

- These units are reliable due to a robust centrifugal compressor design with fewer moving parts and a stable water-cooling system. They are compatible with building management systems for intelligent energy management and operation optimization.

High Energy Efficiency

Large Cooling Capacity

Stable Operation

Quiet Operation

Flexible Installation

Compatibility with Building Management Systems

High Energy Efficiency

- The water-cooled centrifugal unit can achieve a high coefficient of performance (COP), meaning it consumes less energy to provide a significant amount of cooling capacity. The water-cooling system offers more efficient heat transfer compared to air-cooled alternatives, resulting in lower energy consumption and reduced operating costs.

Large Cooling Capacity

- These units are capable of delivering a large cooling output, making them ideal for large-scale commercial buildings, industrial facilities, and data centers. They can handle high cooling loads and maintain a comfortable environment even in demanding applications.

Stable Operation

- The water-cooling process provides a more stable operating temperature for the compressor. This stability helps to reduce wear and tear on components and prolong the lifespan of the unit. It also ensures consistent cooling performance over time..

Quiet Operation

- Water-cooled centrifugal units generally operate more quietly than some other types of air conditioning systems. The water-cooling mechanism reduces the noise generated by the compressor and other components, creating a quieter environment for occupants.

Flexible Installation

- Although these units are often larger in size, they can be installed in various locations depending on the building layout and requirements. They can be installed on rooftops, in basements, or in dedicated mechanical rooms, providing flexibility in design and installation.

Compatibility with Building Management Systems

- Water-cooled centrifugal units can be integrated with building automation systems (BAS) for centralized control and monitoring. This allows for optimized energy management, scheduling, and troubleshooting, enhancing the overall efficiency and reliability of the building’s HVAC system.

Product Specifications

| Product Specification | Details | Product Specification | Details |

| Heating Power | 6.0 kW | Energy Efficiency Rating | A++ |

| Refrigerant Type | R410A | Applicable Area | 50-150㎡ |

| Power Supply Voltage | 220V / 50Hz | Noise Level | ≤25 dB |

| Dual Inverter Technology | Supported | Smart Temperature Control | Supported |

| Remote Control | Mobile App Remote Control | Auto Defrost Function | Supported |

| Operating Temp Range | -15℃ to 45℃ | Weight | 40 kg |

| Dimensions (L x W x H) | 850mm x 300mm x 650mm | Installation Method | Ceiling / Wall Mounted |

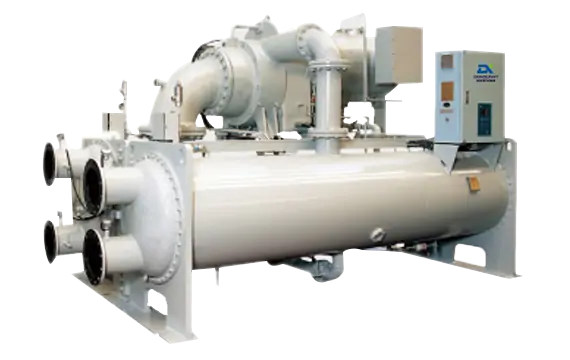

Water-cooled centrifugal unit Feature and Application:

Application:

Large Commercial Spaces

Such as shopping malls and supermarkets. The water-cooled centrifugal unit can handle the massive cooling demands of these large areas with high foot traffic and numerous lighting and electrical equipment.

Industrial Plants:

For cooling machinery and processes in factories. It helps maintain optimal operating temperatures for industrial equipment and prevent overheating.

Data Centers:

To keep the servers and IT equipment cool. The precise temperature control is crucial for the reliable operation of data centers.

Office Complexes:

In large office buildings, it provides a comfortable working environment by efficiently cooling the spaces.

Commercial and Residential Buildings:

Waste heat source heat pump unit recovers heat from ventilation systems, refrigeration equipment, or exhaust gases in large buildings, shopping malls, and residential complexes, which can be used for heating or hot water supply.

Agriculture and Aquaculture:

Can be used in greenhouses or fish farms to maintain optimal temperatures, improving productivity while reducing energy costs.

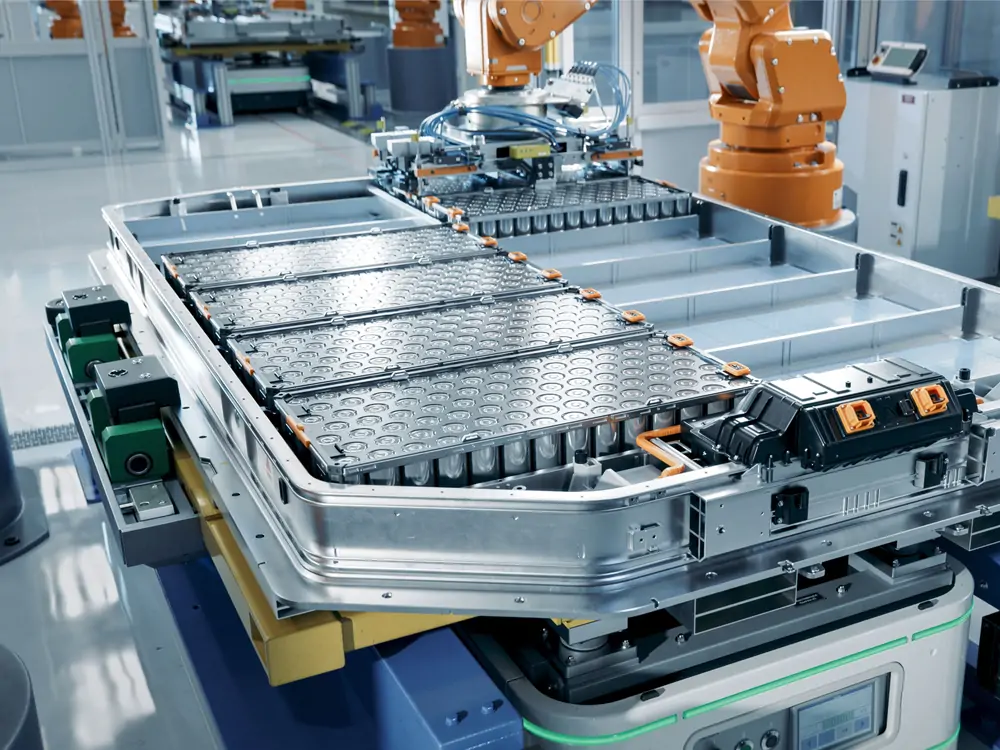

Water-cooled centrifugal unit Details

Working Principle:

The water-cooled centrifugal unit operates by using a centrifugal compressor to compress refrigerant gas. The compressed gas then enters the condenser, where heat is transferred to the cooling water. The cooled refrigerant passes through the expansion valve and enters the evaporator. In the evaporator, the refrigerant absorbs heat from the surrounding air or process fluid, cooling it down. The cooled air or fluid is then distributed to the desired area. The heated cooling water from the condenser is sent to the cooling tower, where it is cooled down by evaporation and returned to the condenser to repeat the cycle. The unit’s operation is controlled by a control system that monitors and adjusts various parameters such as temperature, pressure, and flow rates to ensure optimal performance and energy efficiency. The basic steps include:

Condensation:

The centrifugal compressor compresses the refrigerant gas to a high pressure. This increases the temperature and energy level of the refrigerant.

Compression:

The centrifugal compressor compresses the refrigerant gas to a high pressure. This increases the temperature and energy level of the refrigerant.

Expansion:

The condensed refrigerant then passes through an expansion valve where its pressure is reduced. This causes a drop in temperature.

Expansion and Recycling:

The refrigerant expands and cools through the expansion valve, returning to its original state and repeating the process.

Efficiency and Performance:

The water-cooled centrifugal unit demonstrates exceptional efficiency and performance. In terms of efficiency, it features a high Coefficient of Performance (COP) due to the excellent heat transfer properties of water-cooling and centrifugal compression. Variable-speed drives enable it to adjust to the actual cooling load, saving energy and ensuring optimal efficiency at all times. Some models offer heat recovery capabilities, allowing waste heat to be reused for other purposes, further enhancing energy efficiency. Regarding performance, it has a large cooling capacity, making it ideal for applications like large commercial buildings, industrial facilities, and data centers. It can maintain precise temperature control, crucial for sensitive environments. With a robust design and high-quality components, it offers reliable operation and can run continuously with minimal maintenance. Additionally, many units operate quietly, suitable for locations where noise levels must be kept low, such as hospitals, hotels, and office buildings.

Frequently asked questions

Water-cooled centrifugal units typically require regular maintenance, including checking and cleaning filters, inspecting water circuits for leaks, and ensuring proper operation of the compressor. However, with proper care, they can provide reliable service for many years.

While water-cooled centrifugal units are often used in large commercial and industrial buildings, they can also be used in smaller facilities depending on the cooling load requirements. However, smaller buildings may find other types of cooling systems more cost-effective.

With proper maintenance, a water-cooled centrifugal unit can have a lifespan of 15 to 20 years or more.

The cooling tower cools the water that has absorbed heat from the condenser. The cooled water is then returned to the condenser to continue the cooling process. The cooling tower uses evaporation to remove heat from the water.

Water-cooled centrifugal units can be more environmentally friendly than some other cooling systems as they can be designed to use less energy and have lower greenhouse gas emissions. However, proper disposal of used refrigerants and management of water usage are important considerations for environmental sustainability.